Pingxiang Volmet Import&Export Trading Co., Ltd. 萍乡市沃美特进出口贸易有限公司

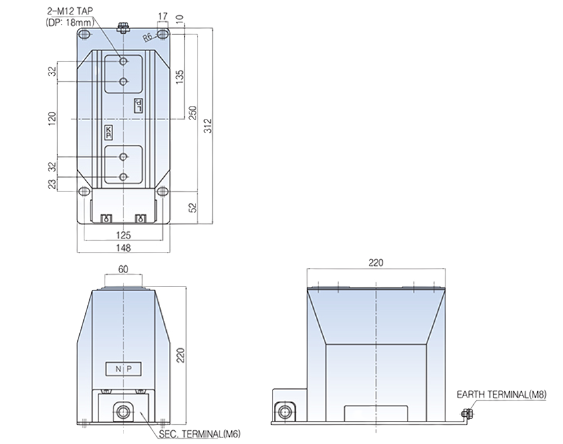

CURRENT TRANSFORMER For Indoor And Outdoor Application

We not only supply APG machine and molds,but also cast epoxy resin products for clients.

Contact Us

CURRENT TRANSFORMER For Indoor And Outdoor Application

Voltage range 12-36KV

Economic Efficiency

for its increase of withstand short time thermal currents over same dimension

No Partial Discharge

Excellent electric Characteristics and Mechanical Strength

Current transformer cast by advanced technology- APG technology,

Easy to handle

in case of changing to the other different

Current transformers / Potential Transformers are a natural extension to our range of products to cater to the Switchgear & Transformer Industry. Complete Range i.e. from 11kV up to 33kV CT/PT’s of Low voltage /Bushing mounted CT’s being manufactured.

Current Transformer Cast By APG Machine Process:

One cavity CT production process:

Two cavities CT production process:

Application:

The APG manufacturing process of epoxy resin casting current transformer(CT)

APG Machine Video

Application:

In AC circuits, transformers are commonly used to convert high voltages into low voltages, and large currents into small currents, which are then used for measurement, control, and protection. This can not only increase the measurement instrument process, facilitate instrument standardization, reduce the voltage and current of the control and protection equipment, but also separate the instrument from the equipment or high-voltage circuit to ensure the safety of the instrument, equipment and staff.

Work Process

The role of the transformer has the following aspects:

Change the high voltage and high current of the primary circuit into the standard position of the secondary circuit, usually the rated secondary voltage is 100V, the rated secondary current is 5A, so that the location measuring instrument and the protection device are standardized, and the insulation level of the secondary equipment can be It is designed according to low voltage, so the structure is light and cheap.

All secondary equipment can be connected with low-voltage, low-current control cables, so that the wiring inside the screen is simple and easy to install. At the same time, it is convenient for centralized processing and can realize remote control and measurement.

The secondary circuit is not restricted by the primary circuit. Y-shaped, △-shaped or V-shaped connection can be used, so the wiring is flexible and convenient. At the same time, when the secondary equipment is maintained, exchanged and adjusted and tested, the operation of the primary system does not need to be interrupted, and it can be achieved only by appropriately changing the secondary wiring.